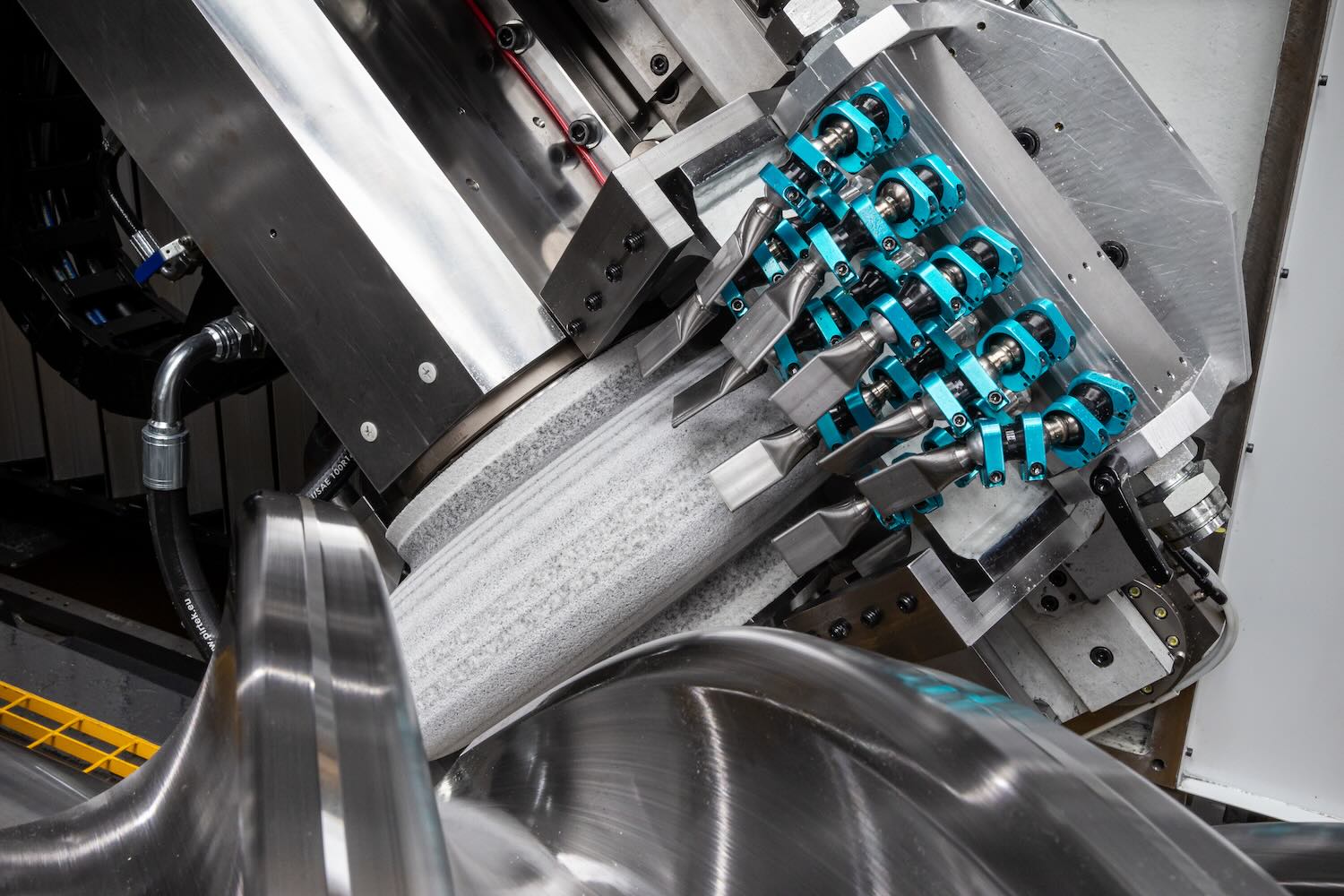

Brand new, for the new era in large-capacity, high-efficiency helical rotor production, the HG500 is quite possibly the most versatile high-precision helical profile grinding machine of its kind.

Maximum flexibility in production strategies

Offering incredible flexibility, the HG500 will rough and finish-grind rotors of as little as 50 mm in diameter, right up to a maximum 510 mm in diameter and 1,500 kg in weight.

In standard configuration, the HG500 can be equipped with either a 500 mm vitrified dressable aluminium oxide grinding wheel for maximum flexibility in production strategies – or use plated CBN roughing and finishing wheels for cost-effective volume production.