The Latest

News & Press

USA-based Delroyd selects PTG-Holroyd’s newly launched precision worm gear grinding centre

Delroyd Worm Gear, the North American manufacturer of precision worm gear drives and a part of Nuttall Gear, a business unit of Altra Industrial Motion, has placed an order for one of PTG-Holroyd’s newly launched HG350-WG worm gear and gear grinding centres. Scheduled for installation in summer 2022, this will be the first of UK-based PTG Holroyd’s new HG350-WG machines to be purchased by an overseas customer.

Advanced Machinery and Productivity Institute (AMPI) receives funding boost for its innovation initiative

Huddersfield 22nd July 2021 – A consortium, led by the National Physical Laboratory (NPL), has secured £22.6m funding for a 5-year innovation initiative, the first for the Advanced Machinery & Productivity Institute (AMPI), which will be based in Rochdale, Greater Manchester. This funding has been provided through UK Research and Innovation’s flagship Strength in Places Fund (SIPF).

Neues Schleifzentrum mit Sinumerik-One-Steuerung

Doppelt zukunftssicher Die neue Zahnradschleifmaschine HG350-G ist die erste Formschleifmaschine von PTG Holroyd mit der Siemens-Steuerung Sinumerik One. Das Paket bietet smarte Features wie Sicherheitsfunktionen, den digitalen Zwilling und ein umfassendes Echtzeit-Monitoring. PTG Holroyd hat mehr als 1,6 Millionen Pfund in die Entwicklung seiner neuen Zahnradschleifmaschine investiert, eine Maschine, die dem Unternehmen einen Vorsprung beim […]

Holroyd HG350-G gear grinding centre is first to use Siemens’ Sinumerik ONE CNC

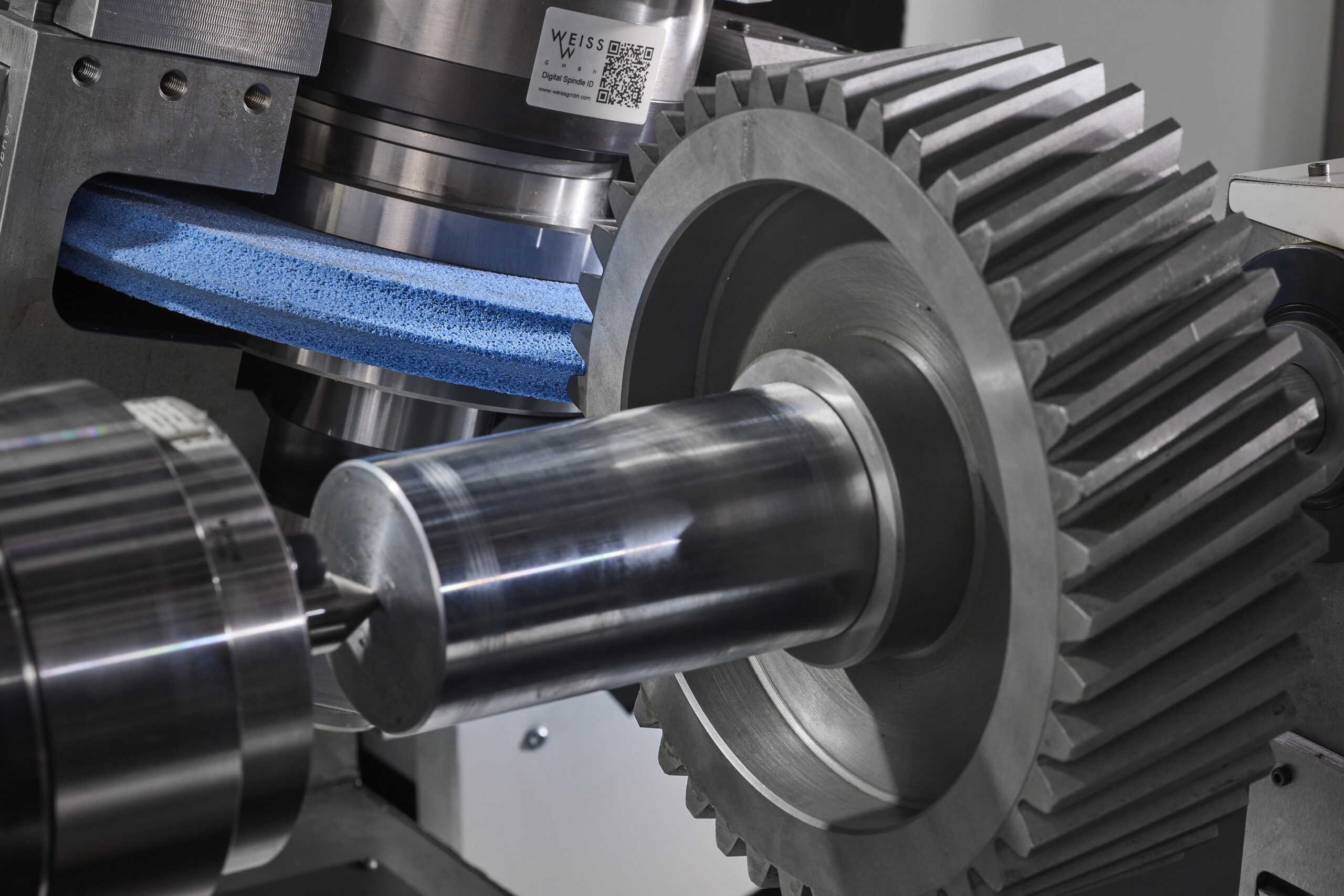

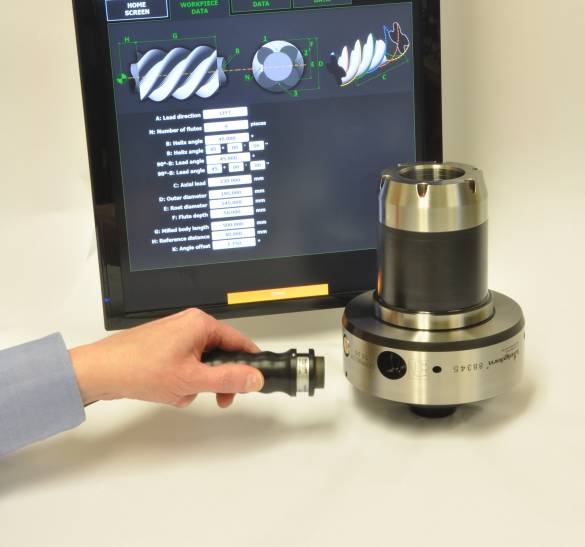

A new precision gear grinding centre from PTG Holroyd hasn’t simply been designed to bring greater levels of efficiency and accuracy to the production of specialised gears and tooth forms. The new machine, called the HG350-G, is also the first from PTG Holroyd – and believed to be the first in the UK – to use Siemens’ new Sinumerik ONE future-proof CNC, the successor to the automation specialist’s 840D CNC.

Major European Train Builders Invest in Powerstir Friction Stir Welding

Specially developed Powerstir friction stir welding (FSW) machines from UK-based Precision Technologies Group (PTG), that incorporate a 30-metre x 4-metre moving gantry, could soon redefine the way in which Europe’s leading manufacturers of railway rolling stock produce aluminium carriage bodies.

New Holroyd Gear Grinding Centre Offers Greater Levels Of Efficiency In Precision Gear, Worm And Screw Production

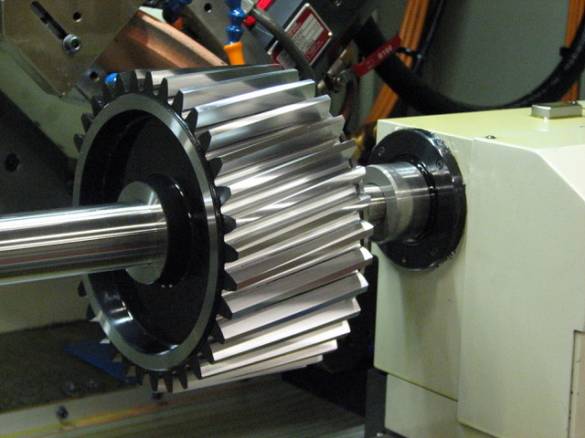

A brand-new gear grinding centre from Holroyd Precision promises to bring even higher levels of intelligence and efficiency to the production of specialised gears and tooth forms. Called the GT350, this latest machine from the Precision Technologies Group (PTG) company has been developed for one-off and batch grinding of precision spur and helical gears, worms and screws of up to 350 mm in diameter. It can also be used to precision grind compressor rotors.

PTG Introduces Powerstir Dual Weld-Head Friction Stir Welding For Electric Vehicle OEMs

UK-based Precision Technologies Group (PTG), the manufacturer of the globally acclaimed Powerstir range of friction stir welding machines, has introduced a number of dual weld-head FSW models specifically for use in the volume production of automotive battery tray floor assemblies from extruded aluminium panels.

Third Holroyd Rotor Milling Machine For Leading Air Compressor Specialist

One of Europe’s premier manufacturers of air compressor technologies has ordered a new EX Series rotor milling machine from Precision Technologies Group company, Holroyd Precision.

Bringing New Levels Of Intelligence To Helical Rotor Production

Precision Technologies Group company, Holroyd Precision, has introduced a number of innovative technologies to its rotor milling and grinding machines that will bring even greater levels of intelligence and efficiency to its customers’ manufacturing strategies.

Discover PTG’s Ultra-Precise Machine Tools and Manufacturing Capabilities at Steelfab 2020

We’re looking forward to presenting the capabilities of our rotor milling and grinding machines, our friction stir welding machines and our sub-contract manufacturing facilities at SteelFab 2020.