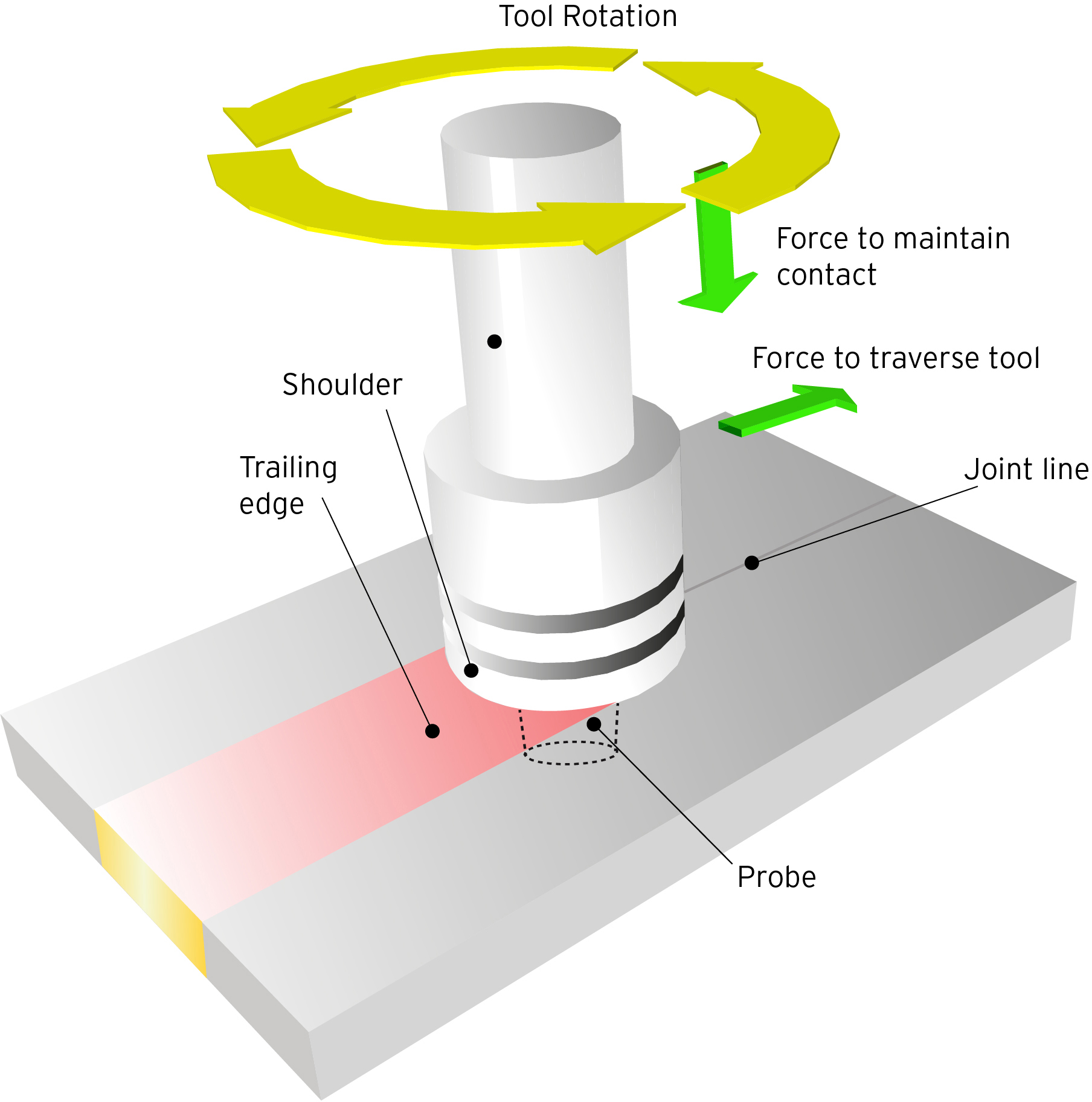

The friction stir welding (FSW) process transforms the parent metal from a solid to a plasticised state, mechanically stirring the materials together under precisely controlled process conditions to form a high-integrity, full penetration welded joint.

A purpose-designed rotational probe is set to the required process parameters for the friction stir welding application. The probe is then brought into contact with the metals to be joined at the joint interface.

Under precisely controlled axis conditions, with closed-loop monitoring of load and position, the probe follows the programmed weld path through the material. As the probe rotates, frictionally generated heat plasticises the surrounding material, creating a locally formable region. As the probe travels, the material at the trailing edge is forged under pressure from the probe shoulder and combines to form a cohesive bond.

Unlike fusion welding, during the friction stir welding (FSW) process the metals to be joined are not molten. This means the weld region can retain grain structure integrity and mechanical properties of the original parent metal.

Benefiting from sophisticated sensing and data-logging, the PTG Powerstir friction stir welding process is effective on flat plates, extrusions, cylindrical components and even on parts of irregular thickness.

Typical friction stir welding process applications

- Electric vehicle battery tray floor assemblies, battery trays and boxes

- Vehicle chassis and structural components

- Car and commercial vehicle body panels

- Locomotive train and carriage panels (aluminium)

- HGVs, truck bodies and space frames

- Heat sinks and electronics enclosures

- Boat and ship panel sections

- Fuel tanks and bulk liquid containers (flat and cylindrical)

- Aluminium bridge sections, architectural structures and frames, pipelines, heat exchangers

- Electrical motor housings

Materials

- Aluminium

- Magnesium

- Copper

- Titanium

- Steel

- Lead

- Zinc

PTG Powerstir dual weld-head friction stir welding for electric vehicle OEMs

In addition to offering conventional single weld-head Powerstir friction stir welding machines, PTG has also developed Powerstir dual weld-head friction stir welding machines. Designed specifically for use in the volume production of automotive battery tray floor assemblies from extruded aluminium panels, the PTG Powerstir dual weld-head process is aimed directly at manufacturers of electric vehicle (EV) skateboard chassis structures and ensures that a tight weld-flatness tolerance is achieved during battery tray floor construction.

A tight weld-flatness tolerance is essential to ensure that each EV battery cell sits perfectly level within its housing. The PTG Powerstir dual weld-head method achieves an even and stable welding process – something that is made possible thanks to PTG’s unique ‘matched’ dual-force control systems and balanced upper and lower head welding parameters. The result is exceptionally stable friction stir welding by both the upper and lower weld heads, producing matched weld seams with balanced heat input. This, in turn, minimises post-weld distortion and equips each welded assembly with a significantly improved flatness tolerance when compared to existing conventional single-side friction stir welding techniques.